Brink®

Droplet Separators

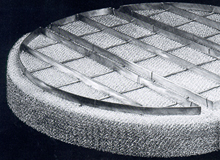

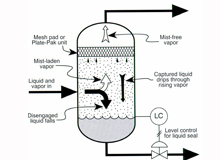

Droplet separators in the form of mesh pads are commonly used in packed towers to separate mechanically created droplets. They can also be used in separate units with a multitude of applications.

PRODUCT DETAILS

For separation of liquid mist a distinction is drawn between mist eliminators which are specially designed for the removal of very small droplets, and droplet separators which can be built as filter candle or mesh pads. You can find more information about filter candles under mist eliminators.

Droplet separators in the form of mesh pads are commonly used in packed towers to separate mechanically created droplets. They can also be used in separate units with a multitude of applications. Brink® Mesh Pads are available in a wide range of materials.

Brink® is a registered trademark of MECS.

Fine mist created by mechanical shearing forces through tower packing or trays, can pass through conventional mesh pads and cause downstream corrosion of valuable equipment. Brink® Mesh Pads capture, collect and return the mist to the tower.

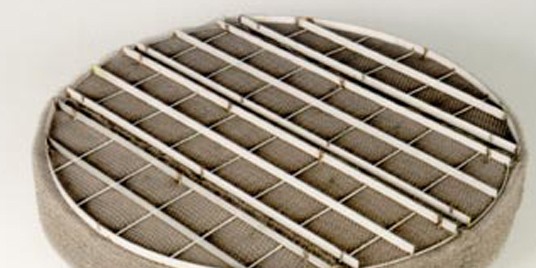

In particular, high performance versions employ a MultiMesh™ design that provides the highest efficiency possible while reducing pressure drop without sacrificing capacity. Brink® Mesh Pad systems made with co-knit fibers offer increased targets for lower gas velocties and smaller droplets. These systems are capable of handling turndown ratios of 50 % or less, whereas conventional pads are more limited.

Brink® Mesh Pad benefits are:

• Low pressure drop

• Low maintenance

• High tolerance to process fluctuations

• Composite MultiMesh™ design in alloy 20, 316 S/S and co-knit for all services

• Co-knit glass or Teflon fibers provide increased efficiency and reduced pressure drop without sacrificing capacity

• Customized efficiency and pressure drop

Brink® Mesh Pads are used in many processes:

• Cooling towers

• Absorbers

• Scrubber systems

• Distillation columns/rectification

• Evaporators