DynaWave® scrubbers

The DynaWave® Reverse Jet Scrubber is the perfect solution for removing particles, quenching hot gases and absorbing acid gases.

PRODUCT DETAILS

Stringent air pollution regulations are requiring refineries, cement kilns, power plants, and chemical manufacturers to remove pollutants, such as SO2, and particulate from flue gas before release to the atmosphere.

In other cases, air pollution control equipment can actually pay for itself if it allows the end user to switch to a cheaper fuel source that contains high levels of sulfur, for example. In either case, wet gas scrubbers offer a proven approach to removing SO2 or other acid gases from a gas stream.

The DynaWave® Reverse Jet Scrubber is the perfect solution for removing particles, quenching hot gases and absorbing acid gases.

The DynaWave® Scrubber is different from conventional scrubbers in that it handles all these functions in the same zone of the scrubber. This straightforward approach reduces both capital and operating costs. Most importantly, this approach allows for minimal equipment inside the vessel, making DynaWave® an extremely reliable scrubber.

DynaWave® is a registered trademark of MECS.

The key to the high DynaWave® performance is the thorough mixing of the gas and scrubbing liquid in the inlet barrel:

1. Gas enters at the top of the vessel and travels down the inlet barrel.

2. Liquid is sprayed into the barrel, counter to the gas flow.

3. The gas collides with the liquid to create a turbulent zone where the gas/liquid interface is continuously and rapidly renewed.

4. Once the momentum of the gas and liquid balances, the liquid reverses direction, and then falls to the base of the vessel.

5. The gas, on exiting the inlet barrel, turns and moves vertically upward through the tower. The gas encounters a set of chevrons that removes remaining liquid droplets.

6. After the chevrons, the gas exits the scrubber.

DynaWave® Reverse Jet Scrubber benefits are:

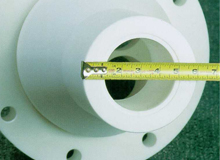

• Virtually unpluggable large, open bore liquid injectors

• No narrow passages and no moveable parts inside the tank

• Can be operated using a variety of reagents: Sodium hydroxide, NaOH, calcium hydroxide, Ca(OH)2, calcium carbonate, CaCO3, magnesium hydroxide, Mg(OH)2

• Simple to operate and low maintenance

• Combines several applications: particle removal, acid gas absorption and hot gas quenching

• High operational reliability

DynaWave® Reverse Jet Scrubbers are used in many processes:

• Sulfuric acid plants

• Metal smelters

• Cement kilns

• Refineries

• Waste incinerating plants

• Titanium dioxide production

• Phosphoric acid

• Various chemical processes