Sulfuric Acid

Sulfuric Acid plants pose many challenges, and corrosion ranks at or near the top of the list. DSD Chemtech offers a number of products and solutions to meet these challenges.

PRODUCT DETAILS

Since we are an MECS agency (a global market leader for sulfuric acid plant design and specialized sulfuric acid products) we have a large range of sulfuric acid products and services.

Thanks to our comprehensive knowledge of processes and our broad range of products, we are able to select the best product for every application.

Since 1925 MECS has been manufacturing catalysts for the sulfuric acid industry using the latest technology. In order to meet your specific needs, we are able to provide customized solutions for Sulfuric Acid plants. Years of experience in the industry mean that we can set new standards every day that guarantee energy efficient plants and processes to whatever the customer’s needs are.

Further information about our products can be found in the download section.

ZeCor® is a registered trademark of MECS.

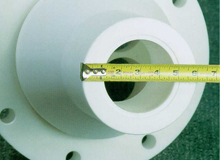

Our corrosion-resistant stainless steel products have been put to the test in thousands of installations and applications. The best brand for strong acid applications is ZeCor®, a corrosion-resistant stainless steel product available exclusively from MECS. We also provide numerous other widely used stainless steel products, such as 310M for Heat Recovery Systems (HRS).

We offer the UniFLO™ Distributor in patented ZeCor® stainless steel, one of the toughest corrosion-resistant materials on the market. We also use a variety of other stainless steels to meet your specific needs. In fact, our equipment has a standard life of 20-plus years. Over the long haul, UniFLO™ Distributors save more than 25 percent over conventional designs for initial capital costs and long term maintenance.

The newest, patented UniFLO™ design gives you all the advantages of a conventional trough-style distributor with many added benefits. Gate assemblies in each trough afford easy flow adjustment – without changing out orifice plates. The result is unparalleled, uniform distribution.

UniFLO™ Acid Distributor benefits are:

- • Uniform acid distribution

- • Reliability

- • Enhanced safety

- • Less maintenance

- • Light-weight construction

- • Durability

- • Low costs

UniFLO™ is a registered trademark of MECS.

DSD Chemtech offers the MonPlex™ Plate Heat Exchanger. This proprietary technology withstands the harsh conditions present in a Sulfuric Acid plant while providing the effective heat transfer needed to maintain catalyst bed temperatures essential for conversion efficiency.

Modular and custom-designed to meet your application, the MonPlex™ Heat Exchanger is compact and available in both cross flow and counter flow configurations. This modular design offers the most flexible and efficient flow arrangements. It also offers significant improvements in design and operational flexibility, including the freedom to select appropriate materials of construction for each heat transfer zone.

ZeCor® Coolers give you the option of using a stainless steel with superior corrosion resistance, and the added benefit of eliminating costs associated with operating traditional cathodic protection systems. Used in numerous applications, ZeCor® Shell and Tube Coolers are virtually maintenance-free. So you avoid costly downtime for inspections and repairs.

We also provide cathodically-protected acid coolers to meet your process conditions, economics and preference. Our Filmgard 4 replaces any existing protection systems with a common, centrally located package for monitoring system performance.

DSD Chemtech is a reliable partner during the modification and optimization of process units or the replacement of existing equipment and tanks.

In corporation with our partners we are in the position to deliver a range of components from small pressure vessels up to single components with diameters up to 7m, 50m length and weights up to 200t. A combination of technical know-how and latest process technologies guarantees a high-quality operation profit.

A wide range of different types and designs was developed to remove visible plume from any gas stream, to decrease droplet emissions, to increase the efficiency of production processes and to protect the downstream equipment from corrosion and fouling within the process.

Brink® is a registered trademark of MECS.

The XLP series catalysts provide the high activity, low pressure drop characteristics desired by most producers. The standard catalyst formulation has been modified to incorporate the essential cesium promoter (CS series) which activates the catalyst at lower temperatures. The cesium-promoted catalyst can be installed in both upper and lower pass applications. Both types of formulations are also available as ribbed ring for higher specific area and lower pressure drop.

GEAR™ – The new MECS catalysts, GR-330 and GR-310, join low pressure drop with increased activity. This saves energy and reduces emissions. They can be used to replace all catalysts in contact towers. The new catalysts’ geometry leads to a lower pressure drop of up to 30%. Combining an optimal design with a better composition delivers higher activity and, therefore, increased performance.

For applications where low gas velocity converter vessels are still used, our solid pellet catalyst provides uniform gas distribution and maximum conversion performance.

With MECS we provide catalyst engineering studies to assist the customer in determining the catalyst needs in a specific plant. A customer sample analysis (activity analysis and hardness determinations for used catalyst samples), and on-site converter-heat exchanger testing (called PeGaSys) are available to fully characterize the sulfuric acid plant operations that assist the customer in maintenance planning.

DOWNLOADS

- DSD Chemtech Brochure (E)

- Brink® Mist Eliminators – Brochure (E)

- Catalyst Cesium promoted – Brochure (E)

- Catalyst GEAR™ – Brochure (E)

- Catalyst XLP – Brochure (E)

- PeGASys™ Service – Brochure (E)

- Acid Coolers – Brochure (E)

- ZeCor® Components (E)

- ZeCor® Piping System (E)

- ZeCor® Towers & Pump Tanks (E)

- ZeCor® UniFlo™ Acid Distributors (E)

- Hybrid MonPlex™ II – Brochure (E)

- MECS® HexPro™ Ferrules (E)

- MECS® HexWall™ (E)

- Sulfuric Acid Plant Operator Training Simulator (E)

- Sulfuric Acid Plants Turnaround Consulting Services (E)